Automotive Extrusion Lines

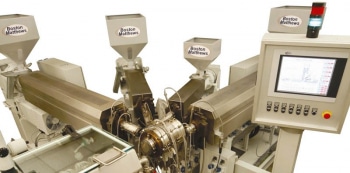

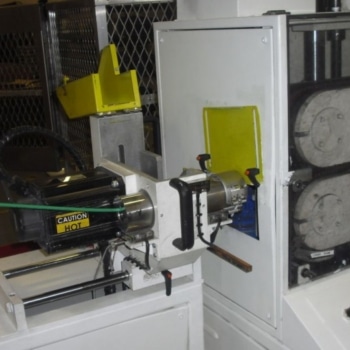

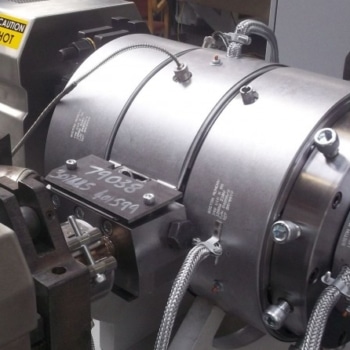

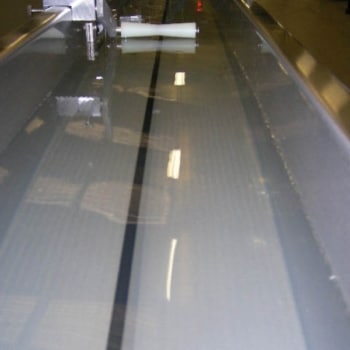

Boston Matthews design and manufacture complete turn-key extrusion lines for Automotive Industry.

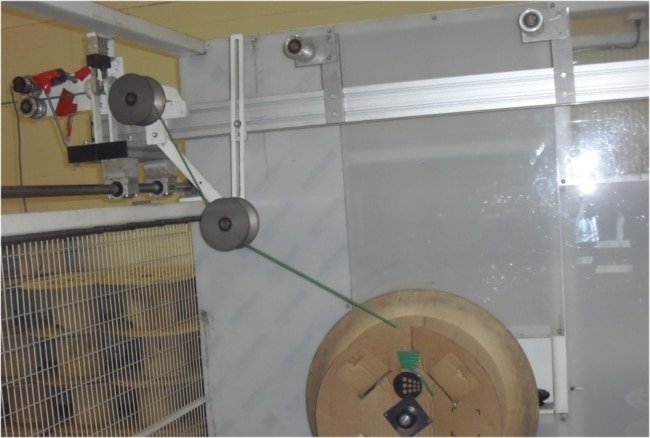

The automotive industry has and continues to demand new advances for multi-layer tubing within their manufacturing operations.

The automotive industry has and continues to demand new advances for multi-layer tubing within their manufacturing operations. Extensive experience of complex multi-layer extrusion has led to many of the world’s leading suppliers to the automotive industry choosing Boston Matthews as their extrusion partner.

Technical Specification / Brochure

Got a question?

Just ask